Cable Protectors and Dropovers Guide

/in Construction Safety, Facility Safety, Parking Lot Safety & Maintenance, Traffic Safety /by TrafficAdm1n73What is Arc Rated Clothing?

/in Facility Safety, Personal Safety (PPE) /by MacAdm1nArc rated clothing is critically important for workplace safety when dealing with electrical wiring and other electrical systems. Electrical work can result in sparks, shocks or even fires. The NFPA 70 is the standard set for installing electrical systems in the United States. The NFPA 70E specifically covers the requirements for employees working with the electrical wiring and equipment. Within these documents are specific guidelines on Arc Flash Rated or “AR” clothing. AR rated clothing is different from flame resistant (FR) clothing. AR clothing is flame resistant, but not all flame resistant clothing can be categorized as AR clothing. The main difference is that AR clothing has been designed and tested to withstand flash hazards better than typical flame resistant cloth. As a result, AR clothing has become the norm within the industry. The additional arc rating measures the insulation from arc flash. This shoulld not be confused with the traditional FR measurables in a flash fire, which are tested with the NFPA 2112.

Traffic Safety Warehouse offers a number of different arc rated coveralls, long sleeve shirts and safety vests that meet the Arc requirements. It is crucial to understand the hazards of each job and how they relate to the test performances. It is also important to understand the state requirements, as the standard code may have been altered at a regional or state level.

Handling FIBC Bags

/in Facility Safety /by MacAdm1nA flexible Intermediate bulk containers, or a FIBC, is a large fabric container that is generally used to store and transport raw material like sand or plastic pellets. A standard light weight bag often holds up to one metric ton, although they do very in size and strength, depending on the manufacturer. The most common method for transporting these bags is to use the loops to lift them with a crane, or to place them on a pallet and move them with a forklift. Due to the weight these bags can accumulate, as well as the static electricity that they can generate, a number of companies involved in the manufacturing of FIBC’s have come together to form the FIBC Association (FIBCA) in order to educate the end users about the best and safest practices.

Although we have summarized the FIBCA’s “safe handling guidelines” below, we recommend that readers take the time to go through the guidelines and disclaimers in full on their website. All responsibility for using the bags safely falls on individual users and the company they work for so be sure to read all manufacturer recommendations thoroughly.

DO’S:

- Ensure your FIBC is right for your product and for your workspace.

- Reach out to your manufacturer with any questions, including those regarding the usage of the bags.

- Follow all regulations, instructions and requirements provided by the manufacture or supplier of your FIBC.

- Use the manufactures instructions to verify that the loops are attached properly and that the bottom discharge is properly sealed.

- Handle your container with devices that meet the requirements outlined by the FIBCA.

- Use every loop provided to lift the bags, and make sure they’re kept vertical. Slings may be recommended to ensure the verticality of the loops.

- Clear all hazards when transporting.

- Adhere to the height and weight limitations provided.

- Use static protective FIBC’s if handling explosive or flammable materials. Always make sure your bag is grounded to avoid static electricity.

- Allow any charge from static electricity to settle before continuing to handle your FIBC.

- Ensure your bag is up-to-date with all standards outlined by the FIBCA.

- Determine if a liner is appropriate for your type of use, and ensure proper use.

- Stack FIBC bags in a pyramid manner, or with proper support.

- Take notice of any water or moisture contamination that may take place in your work area, effecting FIBC’s and their content.

- Store your container and its liner in a non-static area, if possible.

DONT’S:

- Use a FIBC for any purpose other than its’ intended, capable use.

- Handle a damaged bag without the approval of your manufacturer.

- Use a FIBC without fully understanding the best practices.

- Assume that the bags are in perfect condition, without double-checking.

- Handle a bag with devices that do not comply with the handling guidelines, including those with insufficient capacity.

- Use a single hook or other lifting device that will prevent the loops from staying vertical while lifting occurs.

- Use handling devices that are sharp.

- Suspend a bag over anyone or anything.

- Tilt the mask of a forklift forward while handling a FIBC, or lower/raise the bag while in motion.

- Lift or stop suddenly while transporting.

- Exceed the specified capacity of a FIBC.

- Assume a FIBC has any protective ability holding flammable or explosive material.

- Fill or empty a bag that isn’t grounded.

- Allow the FIBC to block your line of sight, or drag/push it along the ground.

- Use a pallet that has exposed nails, or is smaller than the FIBC.

- Stack FIBC’s on top of each other without proper support.

- Try to repair a damaged container with others on top.

- Store your bags exposed outdoors. Sunlight, UAV rays, rain, snow and other weather conditions may also weaken FIBC’s.

- Assume that a FIBC has a shelf-life of any kind

Nitrile Gloves: Featuring Gloveworks Heavy Duty Nitrile Gloves

/in Facility Safety, Personal Safety (PPE) /by TrafficAdm1n73Nitrile gloves are used in many industries including agriculture, automotive, chemical, manufacturing and more. Gloveworks Nitrile Gloves in Orange and Black are one of the favorites among industries that require the use of nitrile gloves for many reasons.

Gloveworks Nitrile Gloves Diamond Texture

Gloveworks nitrile gloves are aggressively textured. That texture provides 60% more surface area than a typical nitrile glove. With over 3000 raised diamonds per glove, the surface area is essentially doubled. A raised diamond pattern texture is highly effective and is also commonly seen in aluminum, steel plates, rubber floor coverings, stair treads and other areas to provide greater surface area and less slippage. In the case of gloveworks nitrile gloves this raised diamond pattern also raised allows more liquid to pass through the channels enabling greater surface contact.

Gloveworks Nitrile Gloves are Thicker

The extra thickness provided by Gloveworks gloves makes them 3x more puncture resistant than simple latex gloves. Nitrile gloves are recommended for us with 67% of chemicals in comparison to latex gloves which are only approved for 28% of chemicals. The added chemical resistance not only keeps workers hands safer but also means they can work longer before having to change gloves. The beaded cuff of the glove prevents ripping and tearing at the base to also enhance the longevity of the glove. The gloves have the same fit and feel as 6 mil gloves but with all the added protection of a 10 mil glove. Better protection and longer lasting gloves help save you money and increase safety at the same time.

Additional Glove Features

Gloveworks will conform to workers’ hands as they get warmed from their body heat to provide better dexterity. They provide great grip while keeping hands comfortable. They are powder free so there is no powder residue left on your hands. We carry Gloveworks Nitrile gloves in both black and fluorescent orange. The orange color can be an important part of PPE wear, especially in environments like automotive garages and manufacturing where lighting might not always be as bright. The hi visibility color makes workers more visible and even helps each worker to be more aware of the placement of their hands as they work.

Gloveworks Heavy Duty Nitrile Gloves Available in Two Colors:

Bollard Protection

/in Construction Safety, Facility Safety, Parking Lot Safety & Maintenance /by TrafficAdm1n73Pedestrian Protection Bollards

Bollard is not a familiar term for a lot of people. Everyone has seen them but might not have known what they were called. Of late, bollards have been in the news more as world events have put more focus on pedestrian safety. Articles in USA Today and the New York times have cited the difference bollards made in saving lives earlier this year in Time Square. In public areas where cars and pedestrians are in close proximity, steel and concrete bollards are often seen to separate cars from entering areas where pedestrians are. In the Times Square incident, the bollards had been added just the year before and their presence stopped a car that was headed the wrong way down a way one way street from doing even more damage then it might have.

Bollard is not a familiar term for a lot of people. Everyone has seen them but might not have known what they were called. Of late, bollards have been in the news more as world events have put more focus on pedestrian safety. Articles in USA Today and the New York times have cited the difference bollards made in saving lives earlier this year in Time Square. In public areas where cars and pedestrians are in close proximity, steel and concrete bollards are often seen to separate cars from entering areas where pedestrians are. In the Times Square incident, the bollards had been added just the year before and their presence stopped a car that was headed the wrong way down a way one way street from doing even more damage then it might have.

Property Protection Bollards

Bollards are not only used for pedestrian safety but are also commonly used to protect buildings and property. Occasionally one will hear about a driver who lost control of their car before heading into a storefront or a restaurant. For building and property protection, steel and concrete bollards are again a common option. Again, more permanent solutions like concrete and steel bollards are typically seen in these circumstances.

Bollards are not only used for pedestrian safety but are also commonly used to protect buildings and property. Occasionally one will hear about a driver who lost control of their car before heading into a storefront or a restaurant. For building and property protection, steel and concrete bollards are again a common option. Again, more permanent solutions like concrete and steel bollards are typically seen in these circumstances.

Bollards for Temporary Traffic Control

Removable bollards are perfect in areas where the safety measures needed may be more temporary. Situations like valet parking, parking lots, schools or loading areas where guidance is needed for traffic for short durations. Removable bollards may have good grip rubber bases or they may be ‘drop in’ bollards that can be anchored to the ground with a steel base as needed and removed later. Some removable bollards even have wheels attached to allow them to be moved into place easily.

Removable bollards are perfect in areas where the safety measures needed may be more temporary. Situations like valet parking, parking lots, schools or loading areas where guidance is needed for traffic for short durations. Removable bollards may have good grip rubber bases or they may be ‘drop in’ bollards that can be anchored to the ground with a steel base as needed and removed later. Some removable bollards even have wheels attached to allow them to be moved into place easily.

Bollard Covers for Quick Aesthetics & Greater Visibility

For bollards that have been in place for a long time and might be looking a little worn, bollard covers are a great option. Your steel bollards may still be doing a great job but they may not be looking their best anymore. Bollard covers can range from fancier, more decorative covers with lights and an architectural look to simpler bollard covers whose main purpose is just to look fresh and increase visibility. If your bollards are in good structural shape then bollard covers may be the perfect, cost effective solution. You can dramatically improve the appearance of an area without spending a lot of money while continuing to protect pedestrians and property.

For bollards that have been in place for a long time and might be looking a little worn, bollard covers are a great option. Your steel bollards may still be doing a great job but they may not be looking their best anymore. Bollard covers can range from fancier, more decorative covers with lights and an architectural look to simpler bollard covers whose main purpose is just to look fresh and increase visibility. If your bollards are in good structural shape then bollard covers may be the perfect, cost effective solution. You can dramatically improve the appearance of an area without spending a lot of money while continuing to protect pedestrians and property.

Bulk Sandbags – How to Use Sandbags, Part 1

/in Construction Safety, Facility Safety, Floods & Emergencies /by TrafficAdm1n73Sandbag Storage and Filling

The Bulk Container Association (FIBCA) has created a set of guidelines for the use and storage of bulk bags in an effort to ensure safety. The guidelines cover everything from bag storage to filling to transportation. We will cover storage and filling in the first of our bulk sandbag use posts.

This article as meant to provide an overview of bulk sandbag use and should not replace a thorough review of the manufacturer instructions for the bag you choose.

Before You Start: Review Sandbag Basics

Always be sure that you are choosing the right bag for the job. Check the manufacturer guidelines to be sure that the material you are storing or moving in the bags is not incompatible with the manufacturer’s intended use BEFORE filling any bags. This includes making sure that the material you place in the bag is safe for that bag and that you know in advance the weight that the bag can safely accommodate.

Sandbag Storage

Bulk bags and sandbags need to be stored in a safe, clean, dry place to protect them from the sun’s UV rays and inclement weather. UV rays and moisture can significantly weaken the strength of the bag over time. Additionally, moisture may damage the contents of the bags if you are trying to store material that is needed for future use. It is highly recommended not to store bags outside but if you must store them outside be sure they are well covered with some type of waterproof covering that will also protect them from UV rays. The FIBCA makes clear that they do not endorse the practice of outdoor storage though as it can have an adverse effect on the stability of bulk bags or sandbags.

Filling Sandbags:

- Be sure that the bag you are going to use has been stored correctly so that it’s integrity is not at risk. There’s nothing worse than filling a bag and having it tear or fail.

- Check the bag over to be sure it is free of any initial tears or punctures.

- If you are using a bag with a bottom discharge chute, make sure the chute is closed correctly.

- Make sure the material going into the bag is compatible with the components of the bag.

- Fill the bag as evenly as you can and be sure it stays stable

- Do not overfill the bag past the manufacturer specifications for the weight the bag can safely handle.

Additionally, if you are filling bags with lift loops or sleeves using a crane or forklift to hold them:

- Make sure that the loops or sleeves are vertical to prevent any undue damage from lateral forces.

- Be sure that there are no sharp edges that could tear the bag and that the fork lift tines are strong enough for the load with rounded edges to prevent tearing.

- Raise and lower the bag smoothly

- If hazardous materials are involved, extra precautions need to be taken to ensure personnel safety. You can read more about additional requirements on the OSHA site.

Traffic Safety Warehouse provides a large assortment of bulk sandbags for an array of jobs. You can always call us at (877) 966-1018 if you have product questions.

View sandbags >>

References:

Flexible Intermediate Bulk Container Association (Fibca). “FIBC Handling Guidelines Part 1 – Storage of Empty FIBCs.” (n.d.): n. pag.FIBCA. FIBCA. Web. <http://fibca.com/wp-content/uploads/2012/07/Part1_Storage_of_Empty_FIBCs.pdf>.

Flexible Intermediate Bulk Container Association (Fibca). “FIBC Handling Guidelines Part 2 – Filling of FIBCs.” (n.d.): n. pag. FIBCA. FIBCA. Web. <http://fibca.com/wp-content/uploads/2012/07/Part2_Filling_of_FIBCs.pdf>.

LED Road Flares – The Advantages of LED Flares

/in Construction Safety, Facility Safety, Traffic Safety /by TrafficAdm1n73LED road flares are quickly replacing the old fashioned traffic flares for many reasons. They offer greater visibility, are water proof and virtually crush proof. Because of their durability and better performance, LED flares are used by police, fire fighters and other first responder crew. Because they are so affordable, they are also becoming an essential piece of equipment for the average person as well. They come in easy to handle packs and fit in the corner of your trunk. At Traffic Safety Warehouse, two of our most popular LED road flares are manufactured by Supreme Supplies and Super Brite. They are both excellent quality and you will be happy with either. For more details on each see below.

- Equipped with 16 super bright LED (red, blue or amber) that give 360° coverage and more than 10,000 hour LED life

- High powered magnet to attach easily to metal surfaces

- Extremely durable, you can drive over it

- Water proof to depths of 100 feet

- Visibility: 300 yards in daylight, up to 1 mile at night

- 10 mile visibility by air makes them great for air traffic landing zones

- The lithium battery provides up to 100 hours of continuous light and has as a 10-year shelf life.

- Comes in a set of 6

View Supreme LED Traffic Flares >>

- 360° of light coverage from 16 super bright LED’s

- Visibility: over 7 miles/visible, pattern light range up to 2 miles.

- 9 flashing patterns

- Powerful magnet to attach the flare to metal surfaces

- Flares are waterproof and float

- Crush and corrosion proof

- Replaceable lithium battery

Spill Containment

/in Facility Safety /by TrafficAdm1n73Spill containment is a very important component of safety in the workplace. Having the necessary equipment on hand to quickly contain a spill and keep it from spreading helps ensure safety for employees and visitors, as well as the environment. There are two levels of spill containment.

Spill containment refers to the steps taken to stop the spread of a spill after any immediate safety issues have been taken care of. Making sure the spill doesn’t spread to a larger area is a priority. Not only will containing the spill to a smaller area mean fewer people and less area are affected but it will make it quicker to get cleaned up. Ideally, your facility will have some measures already in place in anticipation of possible spills like drain guards that remove oil and grease from water or making sure you have an appropriate sized spill kit in close proximity. 5 gallon spill kits might be perfect for a truck driver because they fit easily into the cab of the truck. 62 gallon spill kits are designed for larger spills with DOT approved overpack that can also be used as temporary storage for transportation to a disposal site.

Primary and Secondary Spill Containment

Drums and totes are often used as primary containers. These are the containers that store the liquid to be disposed of. However, in some instances where hazardous materials are involved secondary containment is necessary because the primary containers might fail. The secondary container must be have enough volume available to hold the entire contents of the primary container should the first leak. The base must be intact and free from cracks or leaks.

Related Links:

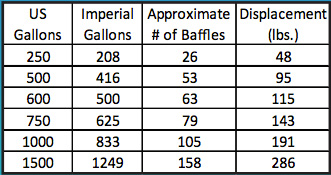

Liquid Stabilizer

/in Facility Safety, Traffic Safety /by TrafficAdm1n73This is a product I found to be very interesting. The video as it shows its ability to stabilize liquids in action. It fascinates me to see the technology that people come up with. The baffles are designed to stabilize the movement of liquid cargo during transport. They are fast and easy to use with a self-locking assembly that requires no tools to put together. They can just be added through the manways (16″ or bigger) allowing you to haul large loads of liquid much safer. See the video below for a demonstration and the graph will show you how many baffles are needed for the size of liquid load.

COMPANY INFORMATION

CUSTOMER SERVICE