Bollard Covers: Low Cost Exterior Upgrades, Easy to Install

/in Outdoor Supplies, Parking Lot Safety & Maintenance, Traffic Safety /by TrafficAdm1n73Cable Protectors and Dropovers Guide

/in Construction Safety, Facility Safety, Parking Lot Safety & Maintenance, Traffic Safety /by TrafficAdm1n73Why Pavement and Line-Striping? – Pavement Striping Business & Tips

/in Parking Lot Safety & Maintenance /by MacAdm1nBelieve it or not, there are high profit margins for contractors doing pavement and line-striping work. Not only are they paid well for their work, but the time and labor put in is not too extensive. Initial costs include the striping machine, however refilling supplies thereafter is not pricey, and generally jobs have $400 minimum requirements to cover overhead. A typical parking lot with 50 parking spaces, a couple handicap stalls and a few arrows can run for $1,500.

Learning how to stripe is not too difficult a task either. Start by re-striping existing stripes and you should get it down in no time. Note that cleaning or sweeping the pavement before marking it is needed to obtain the best results.

Furthermore, repeat business is common, especially in cold weather climates. Laws require proper striping as well as ADA compliant stalls, ensuring that demand is always high. There are always new lots in need of paint, as well as sports fields, roads, airports, sidewalks, curbs and road stencils.

Striping is a great way to earn extra cash. Your schedule can be flexible as long as you get the job done (some even stripe at night), and you’re your own boss! A few things to think about before getting into line striping include:

- The price of equipment

- The price and ability to store equipment.

- The competition in your market.

- How the seasons may affect your market.

- The flexibility in your schedule.

- Your ability to bid jobs and understand your customer base.

- Your scope of work.

- Marketing your business.

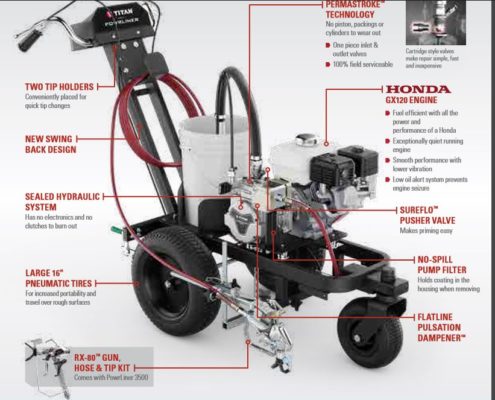

Titan PowrLiner™ 3500 Paint Striping Machine One Gun

When considering what machines and accessories will best suit your needs, make sure to check out Titan’s products, which can be found in our store. Titan is the industry leader, continuously bettering their products after being in the business for about 45 years. They manufacture a number of different stripers, all with unique features that make the process easier and more comfortable for you. Our most popular Titan product is the PowrLiner 3500, which uses the trademarked “PermaStroke Technology”, eliminating the need to replace packings, a piston or a clutch.

In order to make sure that you get the most out of your machines, make sure that you store, clean and maintain the products to the best of your ability. Some helpful tips include:

- Don’t store the sprayer in a high pressure, or cold area.

- Never leave the sprayer filled with water or water based coating.

- Use Liquid Shield to protect against rust, freezing and corrosion.

- Clean the sprayer, spray system, and paint pump after each use.

- Replace the spray tip every 100 gallons.

- Lubricate the packing and piston rod before each use.

- Clean the filters after each use.

- Use gasoline that has a pump octane of 86 or higher.

- Add fuel stabilizer during winter storage.

- Change the engine oil after the first 20 hours of use, and every 100 hours thereafter.

- Use premium quality motor oil.

- Change the air filter after every 25 hours of use, and clean it weekly.

- Release pressure through the gun rather than the pump.

Finally, consider obtaining further resources and information on the best practices in this field. In order to optimize your time and money, it is critical to maintain and use the products the right way. If done, there is a lot of opportunity out there!

What is the Quick-Change™ Feature?

/in Crowd Control, Parking Lot Safety & Maintenance, Safety Signs /by MacAdm1nThe new Quick-Change™ feature allows sign owners to slip their sign substrates into their frames without any tooling or maintenance whatsoever, giving them more versatility than ever before. It is simpler to use than its alternatives, it allows sign owners to print on multiple sides of their poster substrates, and it makes it easy to rotate between a number of different signs. If you’d like to get the most out of your sign frame by using it as many times as possible, the Quick-Change™ is worth the look.

To add the sign to the frame:

- Lift the poster substrate so that the two top corners go into the slot at the top of the frame.

- Lower the poster substrate so that the two lower corners drop into the slot at the bottom of the frame.

To remove the sign from the frame:

- Lift the poster substrate into the top slot, as far up as possible.

- Lower the poster substrate so that it does not drop into the bottom slot, but rather towards the floor.

- Lift the poster substrate upwards, clear of the frame.

Watch how it’s done here:

Shop sign frames with the Quick-Change feature:

How to Install Rubber Speed Bumps

/in Construction Safety, Parking Lot Safety & Maintenance, Traffic Safety /by MacAdm1nRubber speed bumps may be regarded as superior to asphalt for a number of reasons: they’re easy to install and remove, they’re less damaging, and they’re cheaper. Although installing a rubber speed bump can be fairly easy, it’s important to do correctly to ensure it stays in place and lasts.

The first step is to make sure that you have all pieces and tools readily available for the installation. Different products have different specifications, so make sure that you have tools that will allow you to follow their specific guidelines. Besides the actual speed bump, your product may have come with either spikes (recommended for asphalt) or bolts and shields (recommended for concrete). Additionally, you will need a drill and hammer for installation.

Upon gathering the proper tools, follow these steps:

- Place the speed bump where you plan on installing it.

- Drill holes through the designated areas on the top of the bump. Your product should specify the size of your drill bit, matching the size of the spike or lead shield that will ultimately hold the product in place.

- Remove the bump and re-drill the holes to ensure that they are deep enough. Again, the depth depends on the kind of bump you are installing. Once the holes are drilled, remove any debris from the area. If you are using bolts and shields, hammer the lead shields into the holes before placing the speedbump back into position. Additionally, it may be recommended to fill the holes and layer the bottom of the product with an adhesive.

- Once the speed bump is back into position over the holes, secure it in place. If you are using spikes, then you will hammer each spike into place. If you are using bolts and shields, then you will tighten the bolt into the shield at this stage. Make sure that the speed bump is as secure as possible to ensure proper usage, and minimal damage. A ratchet may be used to securely tighten each bolt.

Note that it is recommended to remove rubber speed bumps before winter to prevent snow plows from destroying the product. Leave at least a few inches between speed bumps to allow for draining and possible expansion. Most rubber speed bumps are not designed for speeds exceeding 15 MPH.

Parking Lot Safety

/in Parking Lot Safety & Maintenance, Safety Signs /by TrafficAdm1n73The National Safety Council reports that over 500 deaths and 60,000 injuries occur in parking lots and that number is on the rise. They cited the primary reason as the increase in mobile devices by both pedestrians and drivers.

According to a poll from the National Security Council*, respondents said they would do the following while driving their car through a parking lot:

- Program GPS – 63%

- Send or receive emails – 50%

- Use social media – 52%

- Take photos or watch videos – 49%

- Use a smartwatch – 43%

- Surf the Internet – 43%

- Video chat – 42%

View the CBS video below to see the full story.

Parking Lot Safety Tips

- Put your phone away and no earbuds. Both your eyes and your ears should be engaged to watch for traffic and listen for moving cars.

- Be alert to your surroundings. Pedestrians should keep their eyes up and off any screens and moving to scan their surroundings like they would at a street crossing. Drivers should be trying to scan the full 360 degrees before backing out of their space.

- Pedestrians don’t assume that drivers can see you. More often than not the pedestrian sees the car moving before the driver will see the pedestrian walking.

- Walking in groups is better for both general safety and for helping drivers to see you.

- Avoid parking next to someone who is parked at an angle when possible.

- Wear the right shoes in slippery weather to help avoid falling in the parking lot.

- Pedestrians should not take shortcuts between cars. Drivers are typically not expecting people to appear between cars.

- During the day it is suggested that you park further away from the building where it is less congested. At night you will want to park closer so you have less distance to walk to your car (especially if you are by yourself) and so you are closer to building lights.

While the responsibility lies with individuals to be alert and take care for both their own lives and the lives of others, there may be some products that will help to keep your parking lot safer.

Create Your Own Sign with Custom Message:

Parking Lot Safety Reference Links:

http://www.safetyandhealthmagazine.com/articles/13340-avoid-parking-lot-hazards

http://www.hsc.wvu.edu/safety/general-safety/parking-lot-safety/

*http://www.nsc.org/Connect/NSCNewsReleases/Lists/Posts/Post.aspx?ID=164

Bollard Protection

/in Construction Safety, Facility Safety, Parking Lot Safety & Maintenance /by TrafficAdm1n73Pedestrian Protection Bollards

Bollard is not a familiar term for a lot of people. Everyone has seen them but might not have known what they were called. Of late, bollards have been in the news more as world events have put more focus on pedestrian safety. Articles in USA Today and the New York times have cited the difference bollards made in saving lives earlier this year in Time Square. In public areas where cars and pedestrians are in close proximity, steel and concrete bollards are often seen to separate cars from entering areas where pedestrians are. In the Times Square incident, the bollards had been added just the year before and their presence stopped a car that was headed the wrong way down a way one way street from doing even more damage then it might have.

Bollard is not a familiar term for a lot of people. Everyone has seen them but might not have known what they were called. Of late, bollards have been in the news more as world events have put more focus on pedestrian safety. Articles in USA Today and the New York times have cited the difference bollards made in saving lives earlier this year in Time Square. In public areas where cars and pedestrians are in close proximity, steel and concrete bollards are often seen to separate cars from entering areas where pedestrians are. In the Times Square incident, the bollards had been added just the year before and their presence stopped a car that was headed the wrong way down a way one way street from doing even more damage then it might have.

Property Protection Bollards

Bollards are not only used for pedestrian safety but are also commonly used to protect buildings and property. Occasionally one will hear about a driver who lost control of their car before heading into a storefront or a restaurant. For building and property protection, steel and concrete bollards are again a common option. Again, more permanent solutions like concrete and steel bollards are typically seen in these circumstances.

Bollards are not only used for pedestrian safety but are also commonly used to protect buildings and property. Occasionally one will hear about a driver who lost control of their car before heading into a storefront or a restaurant. For building and property protection, steel and concrete bollards are again a common option. Again, more permanent solutions like concrete and steel bollards are typically seen in these circumstances.

Bollards for Temporary Traffic Control

Removable bollards are perfect in areas where the safety measures needed may be more temporary. Situations like valet parking, parking lots, schools or loading areas where guidance is needed for traffic for short durations. Removable bollards may have good grip rubber bases or they may be ‘drop in’ bollards that can be anchored to the ground with a steel base as needed and removed later. Some removable bollards even have wheels attached to allow them to be moved into place easily.

Removable bollards are perfect in areas where the safety measures needed may be more temporary. Situations like valet parking, parking lots, schools or loading areas where guidance is needed for traffic for short durations. Removable bollards may have good grip rubber bases or they may be ‘drop in’ bollards that can be anchored to the ground with a steel base as needed and removed later. Some removable bollards even have wheels attached to allow them to be moved into place easily.

Bollard Covers for Quick Aesthetics & Greater Visibility

For bollards that have been in place for a long time and might be looking a little worn, bollard covers are a great option. Your steel bollards may still be doing a great job but they may not be looking their best anymore. Bollard covers can range from fancier, more decorative covers with lights and an architectural look to simpler bollard covers whose main purpose is just to look fresh and increase visibility. If your bollards are in good structural shape then bollard covers may be the perfect, cost effective solution. You can dramatically improve the appearance of an area without spending a lot of money while continuing to protect pedestrians and property.

For bollards that have been in place for a long time and might be looking a little worn, bollard covers are a great option. Your steel bollards may still be doing a great job but they may not be looking their best anymore. Bollard covers can range from fancier, more decorative covers with lights and an architectural look to simpler bollard covers whose main purpose is just to look fresh and increase visibility. If your bollards are in good structural shape then bollard covers may be the perfect, cost effective solution. You can dramatically improve the appearance of an area without spending a lot of money while continuing to protect pedestrians and property.

Traffic Cones for Sale

/in Construction Safety, Crowd Control, Parking Lot Safety & Maintenance, Traffic Safety /by TrafficAdm1n73For a limited time you can get EXTRA savings on quality traffic cones.

How to Choose and Use Wheel Chocks

/in Parking Lot Safety & Maintenance /by TrafficAdm1n73Wheel chocks are a critical tool to have when working on a vehicle that has the potential to roll. Usually, wheel chocks are used when the vehicle needs to be lifted at one end for maintenance purposes. Sometimes wheel chocks are used for larger vehicles parked on an incline, to keep them from rolling downhill.

Determining the Right Size Wheel Chock to Use

Measure the height of the tire you need to secure using a tape measure. Most professionals suggest buying a wheel chock that is about one quarter the height of your tire. Once you have gotten the correct size wheel chock, you will want to be sure that the wheel chock fits snugly next to the tire. In some instances it is better to use more than one wheel chock. For instance, if you have a vehicle on an incline or a heavier vehicle you will typically want to use at least two wheel chocks and maybe even more (depending on the weight of the vehicle and the grade of the incline). Again, you will want to make sure each wheel chock is placed snugly up next to the tire. Larger vehicles like RVs and trucks will typically guide you to use 4 wheel chocks so that both the front and back end tires are secure. You can get more information by looking in your owner’s manual for the vehicle you plan to secure.

At Traffic Safety Warehouse we have a large supply of wheel chocks for all different types of needs. The majority of our wheel chocks are made of either tough recycled rubber or molded urethane. There is good reason for this. Rubber and urethane wheel chocks last longer and are more resistant to weather damage and abrasion. Urethane wheel chocks may also be more resistant to damage from oils and solvents.

Below are just a few examples of the many types of chocks we carry at Traffic Safety Warehouse.

Popular Wheel Chocks

Aircraft Wheel Chocks:

Heavy Equipment and Mining Wheel Chocks:

COMPANY INFORMATION

CUSTOMER SERVICE