MUTCD Regulatory Sign Designations

A listing of some of the most common MUTCD regulatory signs and their designations.

A listing of some of the most common MUTCD regulatory signs and their designations.

Traffic Safety Warehouse is one of the biggest distributors of Plasticade products. Everything from Plasticade barricades to traffic cones to sign stands. Every year Plasticade is the innovator of new and better traffic and business safety products and they continue to be a leader in value, quality and protectors of the environment. We pass on that great value straight to our customers, giving them the best pricing in the market for every Plasticade product we carry.

Below are just some of the many Plasticade product lines we carry:

Plasticade Signs and Sign Stands >>

Avalon Crowd Control Barrier from Plasticade >>

Plasticade Speed Bumps and Parking Stops >>

Plasticade Barricade Lights >>

All Plasticade products are thoroughly tested and made to meet or exceed the standards set by the Federal Highway Administration. If you have any questions about any of our Plasticade products just give us a call at 877-966-1018. You can also get more details about Plasticade products on the Plasticade website.

Summer is our busiest season for barricades. From traffic barricades for road safety to crowd control for summer concerts and events, there is a big need for barriers to block, channel and direct people and cars during the summer. In most instances, the needs are temporary and it is important to have barriers that are easy to move but still sturdy enough to do the job and stay in place. We wanted to take a few minutes to spotlight some great barricade options for you to help you with your summer safety and crowd control needs:

These are great because you can design your space exactly as you want it, creating angles and making the length of the barrier as long as needed easily by just snapping the segments together. Some examples of this type of barricade are:

|

|

Avalon Crowd Control Barricades

|

Movit® Portable Plastic Barricade

|

These barricades are made for super fast set-up and takedown. They are very lightweight, easy to store and expand out from several feet to a 10 times their initial length.

|

|

Crowdstopper Steel Barricades

|

Extended Width Portable

|

These barricades are made for super fast set-up and takedown. They are very lightweight, easy to store and expand out from several feet to a 10 times their initial length.

|

|

Water Filled Barrier

|

ATM50 Water Filled Barricade

|

We are kicking off 2015 with the lowest prices on traffic cones. Our traffic cones have always been priced well but now we can bring them to you for a lower price than ever while still keeping that same great quality you’ve come to know us for. We invite you to look around and we think you’ll find these are the best prices for packaged traffic cones out there.

Delineators are used in many different ways. Because they are lightweight and easy to move and store, they are a great option for temporarily redirecting traffic, blocking areas and temporary road closures. Unlike Bollards which tend to be heavier and used more as an obstruction to traffic and to protect from ramming, delineators are lighter weight and serve a more visual capacity to help direct traffic. However, they are still sturdy and their flexible material will withstand impact if needed though they might not stay upright.

There are different versions of delineators. One of the most common is the simple open top delineator which is highly visible and portable. They can be purchased with or without reflective bands. The ring top delineator and claw delineators are similar but have an opening at the top to allow for use of caution tape with the delineator. The caution tape can either be held in the claw or wrapped around and through the ring.

One of the popular delineator models is the DP 200 Series post which is a 3-inch round channelizer made of polyurethane. Polyurethane is the toughest flexible plastic available and is extremely flexible. Even at extreme temperatures it returnsto an upright position after impact. The DP 200 posts are highly visible both day and night and help to delineate driving lanes with bright colors and reflective sheeting. It has been NTPEP tested and meets the requirements of NCHRP 350 for Category 1 Devices.

The most important things to look for in selecting delineators is durability and visibility. All the delineators at Traffic Safety Warehouse meet MUTCD (Manual on Uniform Traffic Control Devices) standards. If you need help in determining the best traffic control device for your project, give us a call and we will be happy to help you.

An alternative method for portable crowd control is replacing the bulky metal fencing of the past. Avalon Barriers are a temporary crowd control solution that are sturdy, affordable and easy to use. These barriers are built of a durable recycled polyethylene plastic. The blow molded technology gives them great strength while allowing them to remain lightweight (only 24 pounds each). The easily withstand the elements, impact and all kinds of wear and tear. They are made 100% recyclable and provide high visibility.

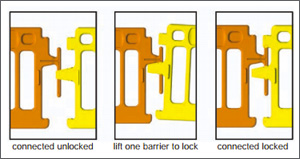

The unique interlocking design of these barriers allow them to be used with several different configurations and at different angles. This makes them ideal for not just level ground, but also for sloping terrain and even over street curbs.

Avalon Crowd Control barriers can be used indoors or outdoors. Some common indoor uses are indoor events and temporary excavations. Outdoors they are often used for construction sites, road work public events and even airports or other large public areas where traffic control is needed.

The Avalon barriers have high visibility anti-trip feet made from dense, heavy molded plastic that provides ballast. The anti-trip feet are flexible too in that they can be turned to be flush with the surface for easier transport and storage.

They come with an recessed area large enough to easily insert retroreflective sheeting for even higher visibility. Logos and signs can also be placed in that area. Additionally, each barrier comes with 4 pre-molded holes in the center to allow signs approximately 16″ x 22″ wide.

Avalon Crowd Control Barriers are available in four high visibility colors – Yellow, Orange, Blue and White.

Presented by Traffic Safety Warehouse Presented by Traffic Safety Warehouse

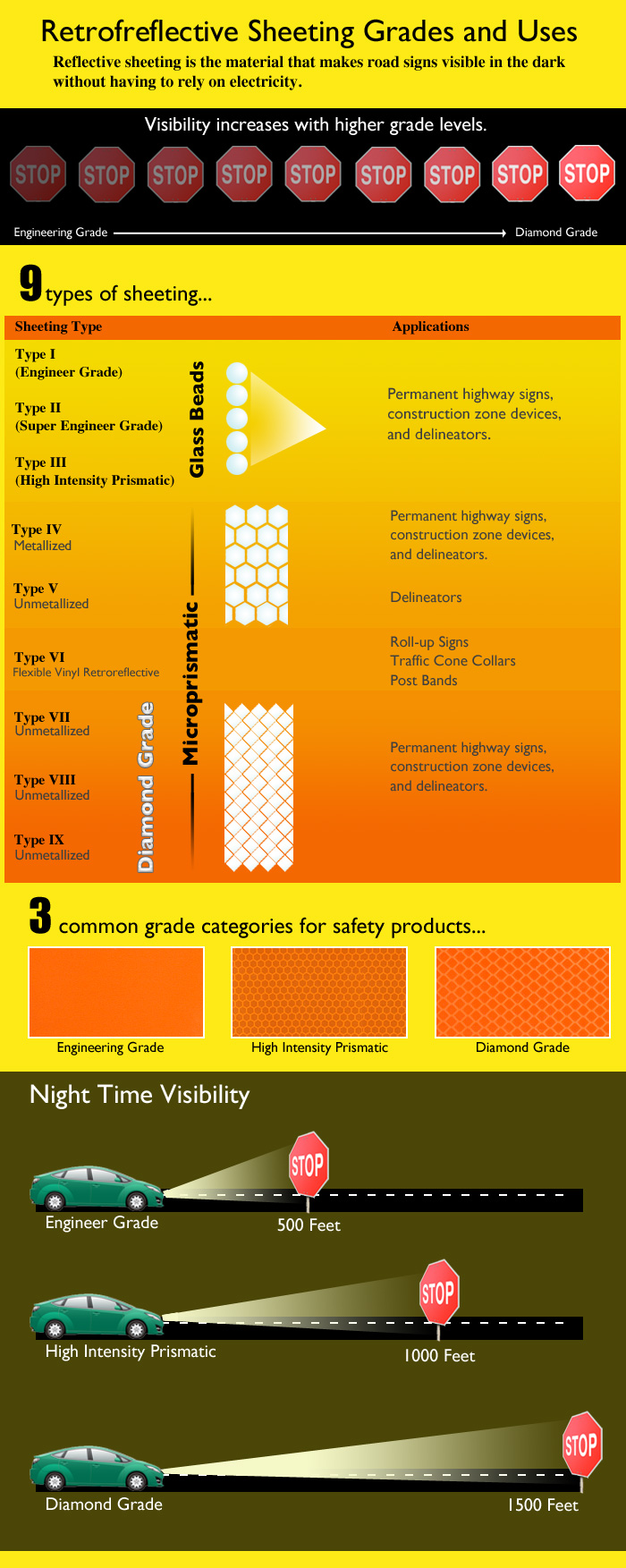

Retroreflective Sheeting TranscriptReflective sheeting is the material that makes road signs visible in the dark without having to rely on electricity. Visibility increases with increasing grades of reflective sheeting with Diamond grade providing the most visibility for signs. 9 Types of Sheeting

3 common grade categories for safety products:Engineering Grade,High Intensity Prismatic and Diamond Grade Night Time VisibilityTypical night time visibility measures: |

Reflective Sheeting Products: You may embed this informative graphic on your site by copying and pasting one of the options below: Full Size Graphic (700px) |

*Information References:

ww.dot.state.mn.us

safety.fhwa.dot.gov

Selecting Traffic Sign Materials

LED road flares are quickly replacing the old fashioned traffic flares for many reasons. They offer greater visibility, are water proof and virtually crush proof. Because of their durability and better performance, LED flares are used by police, fire fighters and other first responder crew. Because they are so affordable, they are also becoming an essential piece of equipment for the average person as well. They come in easy to handle packs and fit in the corner of your trunk. At Traffic Safety Warehouse, two of our most popular LED road flares are manufactured by Supreme Supplies and Super Brite. They are both excellent quality and you will be happy with either. For more details on each see below.

View Supreme LED Traffic Flares >>

Traffic barricades (also known as safety or road barricades) are used to control the flow of traffic in a specified area. They are used at construction sites, accident scenes, as roadblocks, at schools and in a variety of other crowd control situations. There are many different types of road barricades in varying sizes, weights and strengths. So it is important to choose the type of barricade that will best serve your needs. This is a quick traffic barricade overview for those who are just getting acquainted with the types of barricades and their uses that we hope you will find helpful.

Type I Barricades

Type I BarricadesThe Type I Barricade is so named because it has only one reflective rail. Typically it is at least 24 inches wide with orange and white stripes alternating at a 45 degree angle. Sometimes, a second non-reflective rail is added to help give it a more stable base of support. Often Type I Barricades are used for pedestrian traffic control and are used on low speed roads.

Type II Barricades

Type II BarricadesType II Barricades have two reflective rails, also with alternating orange and white stripes. Because the bottom portion of the barricade is also a reflective surface, these generally offer better visibility at night than the Type I Barricades. These barricades also meet the requirements for use on expressways or other higher speed roads.

Type III Barricades

Type III BarricadesType III Barricades are larger and have (yes you guessed it) three reflective panels with alternating orange and white stripes. They are at least 4 feet wide (or larger) and are most often used for road closings because of their size and visibility. You have seen these types of barricades positioned across roadways for detours, road closing and other types of traffic control.

A-Frame Barricades

A-Frame BarricadesA-Frame Barricades typically include a pair of A Frame barricade legs plus a two-sided reflective barricade board. Often they are used to keep a safe distance for workers or pedestrians on roadway work sites or for events needing crowd control.

Traffic Barrels

Traffic BarrelsTraffic Barrels (also referred to as channelizer drums) are also used at construction sites and have alternating white and orange reflective bands. They typically have a rubber base that helps them to remain upright during strong winds or when hit by a vehicle. Most have a handle on top for easy pick up and carry as well as to provide a place to place a barricade light for increased visibility at night.

Sign visibility in construction, school and pedestrian zones has always been a big priority for increasing safety. With advances in technology, there are better options available to help decrease the likelihood of accidents. To understand reflectivity and visibility, it is helpful to understand a few important terms first.

Sheeting – is the front of the sign that is attached to the substrate. The sheeting helps determine both the retroreflectivity and the sturdiness of the sign. The majority of traffic signs are required to be reflective according to the the Manual on Uniform Traffic Control Devices (MUTCD) and OSHA.

Retroreflectivity – retroreflectivity is a measure of a materials’s a ability to reflect light back to its originating source and affects the visibility of the sign it’s used on. Engineer grade reflective was once the standard for sheeting material on reflective signs but new FHWA regulations have replaced this material with materials like High-Intensity (Prismatic) Reflective and Diamond Grade Reflective. Prismatic reflective sheeting meets all of the FHWA, MUTCD and OSHA requirements. Diamond Grade Reflective is now the standard used when very high retroreflectivity is needed to ensure greater visibility. Hilly roadways, roads with sharp turns and/or really dim lit roads are all candidates for this type of sheeting material.

Traffic Safety Warehouse carries a huge assortment Engineer Grade products, High Intensity Prismatic Sheeting products and Diamond Grade Sheeting safety products including barricades, channelizers and diamond grade tape. If you have questions concerning which is the most appropriate grade for your project, just give us a call.

More Resources on Sign Reflectivity and Visibility Requirements:

FHWA Sign Retroreflectivity Requirements