Why Pavement and Line-Striping? – Pavement Striping Business & Tips

Believe it or not, there are high profit margins for contractors doing pavement and line-striping work. Not only are they paid well for their work, but the time and labor put in is not too extensive. Initial costs include the striping machine, however refilling supplies thereafter is not pricey, and generally jobs have $400 minimum requirements to cover overhead. A typical parking lot with 50 parking spaces, a couple handicap stalls and a few arrows can run for $1,500.

Learning how to stripe is not too difficult a task either. Start by re-striping existing stripes and you should get it down in no time. Note that cleaning or sweeping the pavement before marking it is needed to obtain the best results.

Furthermore, repeat business is common, especially in cold weather climates. Laws require proper striping as well as ADA compliant stalls, ensuring that demand is always high. There are always new lots in need of paint, as well as sports fields, roads, airports, sidewalks, curbs and road stencils.

Striping is a great way to earn extra cash. Your schedule can be flexible as long as you get the job done (some even stripe at night), and you’re your own boss! A few things to think about before getting into line striping include:

- The price of equipment

- The price and ability to store equipment.

- The competition in your market.

- How the seasons may affect your market.

- The flexibility in your schedule.

- Your ability to bid jobs and understand your customer base.

- Your scope of work.

- Marketing your business.

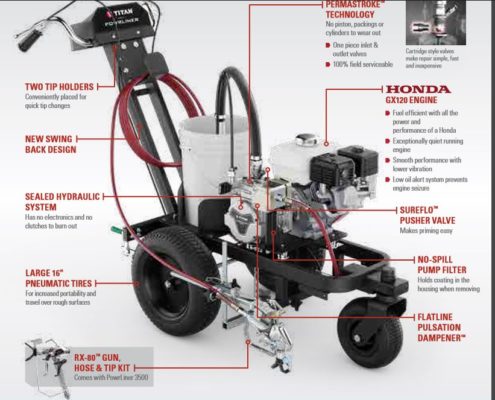

Titan PowrLiner™ 3500 Paint Striping Machine One Gun

When considering what machines and accessories will best suit your needs, make sure to check out Titan’s products, which can be found in our store. Titan is the industry leader, continuously bettering their products after being in the business for about 45 years. They manufacture a number of different stripers, all with unique features that make the process easier and more comfortable for you. Our most popular Titan product is the PowrLiner 3500, which uses the trademarked “PermaStroke Technology”, eliminating the need to replace packings, a piston or a clutch.

In order to make sure that you get the most out of your machines, make sure that you store, clean and maintain the products to the best of your ability. Some helpful tips include:

- Don’t store the sprayer in a high pressure, or cold area.

- Never leave the sprayer filled with water or water based coating.

- Use Liquid Shield to protect against rust, freezing and corrosion.

- Clean the sprayer, spray system, and paint pump after each use.

- Replace the spray tip every 100 gallons.

- Lubricate the packing and piston rod before each use.

- Clean the filters after each use.

- Use gasoline that has a pump octane of 86 or higher.

- Add fuel stabilizer during winter storage.

- Change the engine oil after the first 20 hours of use, and every 100 hours thereafter.

- Use premium quality motor oil.

- Change the air filter after every 25 hours of use, and clean it weekly.

- Release pressure through the gun rather than the pump.

Finally, consider obtaining further resources and information on the best practices in this field. In order to optimize your time and money, it is critical to maintain and use the products the right way. If done, there is a lot of opportunity out there!