https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/02/fibc-bags.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732020-02-26 03:00:492020-02-29 20:30:05FIBC: Flexible Intermediate Bulk Container

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/02/fibc-bags.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732020-02-26 03:00:492020-02-29 20:30:05FIBC: Flexible Intermediate Bulk ContainerLatest Traffic and Safety Articles:

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/02/fibc-bags.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732020-02-26 03:00:492020-02-29 20:30:05FIBC: Flexible Intermediate Bulk Container

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/02/fibc-bags.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732020-02-26 03:00:492020-02-29 20:30:05FIBC: Flexible Intermediate Bulk Container https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/02/pavement-marking-striping-paint.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732020-02-17 22:17:142024-01-01 14:14:13Best Parking Lot and Road Striping Paints

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/02/pavement-marking-striping-paint.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732020-02-17 22:17:142024-01-01 14:14:13Best Parking Lot and Road Striping Paints https://blog.trafficsafetywarehouse.com/wp-content/uploads/2019/12/crowdcade-crowd-control.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732019-12-03 03:44:072024-01-28 10:28:13Crowdcade: The Ultimate Crowd Control Barricade from Plasticade

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2019/12/crowdcade-crowd-control.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732019-12-03 03:44:072024-01-28 10:28:13Crowdcade: The Ultimate Crowd Control Barricade from Plasticade https://blog.trafficsafetywarehouse.com/wp-content/uploads/2019/07/used-traffic-cones-vs-new.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732019-07-12 01:10:032020-02-29 21:09:45Used Traffic Cones: Used Traffic Cone Pricing vs New

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2019/07/used-traffic-cones-vs-new.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732019-07-12 01:10:032020-02-29 21:09:45Used Traffic Cones: Used Traffic Cone Pricing vs New https://blog.trafficsafetywarehouse.com/wp-content/uploads/2019/06/bollard-covers.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732019-06-04 02:54:222020-02-29 21:14:21Bollard Covers: Low Cost Exterior Upgrades, Easy to Install

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2019/06/bollard-covers.jpg

202

300

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732019-06-04 02:54:222020-02-29 21:14:21Bollard Covers: Low Cost Exterior Upgrades, Easy to Install https://blog.trafficsafetywarehouse.com/wp-content/uploads/2019/05/cable-protectors-guards.jpg

336

500

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732019-05-04 22:55:362020-02-17 22:24:51Cable Protectors and Dropovers Guide

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2019/05/cable-protectors-guards.jpg

336

500

TrafficAdm1n73

https://blog.trafficsafetywarehouse.com/wp-content/uploads/2020/10/traffic-safety-logo.png

TrafficAdm1n732019-05-04 22:55:362020-02-17 22:24:51Cable Protectors and Dropovers Guide

Traffic Cone Accessories and Applications

A traffic cone is the paper clip or rubber band of the traffic…

What is Arc Rated Clothing?

Arc rated clothing is critically important for workplace safety…

Why Pavement and Line-Striping? – Pavement Striping Business & Tips

Believe it or not, there are high profit margins for contractors…

Best Safety Vest – Finding the Best Safety Vest for Your Needs

The most important factor in determining the best safety vest…

The Ultimate Barricade Guide

Barricade Types

Knowing which barricade to use can be a bit…

What is the Quick-Change™ Feature?

The new Quick-Change™ feature allows sign owners to slip their…

LED Signs: What to Know

When it comes to signage, grabbing attention is of vital importance.…

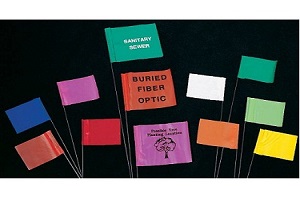

Color Code for Utility Marking

Breaking ground for construction, farming, or any other reason…

Barricade Lights

Barricade lights are important equipment additions when it comes…

Handling FIBC Bags

A flexible Intermediate bulk containers, or a FIBC, is a large…

What are Channelizers

Channelizers are traffic safety products used to alert and direct…

How to Install Rubber Speed Bumps

Rubber speed bumps may be regarded as superior to asphalt for…

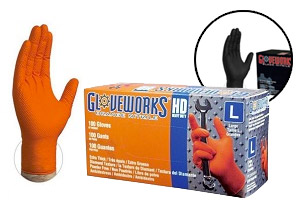

Nitrile Gloves: Featuring Gloveworks Heavy Duty Nitrile Gloves

Nitrile gloves are used in many industries including agriculture,…

Parking Lot Safety

The National Safety Council reports that over 500 deaths and…

Bollard Protection

Pedestrian Protection Bollards

Bollard is not a familiar term…

COMPANY INFORMATION

CUSTOMER SERVICE